The Rise of Low-MOQ Supplement Manufacturing in Europe: Built for Trend-Driven Launches

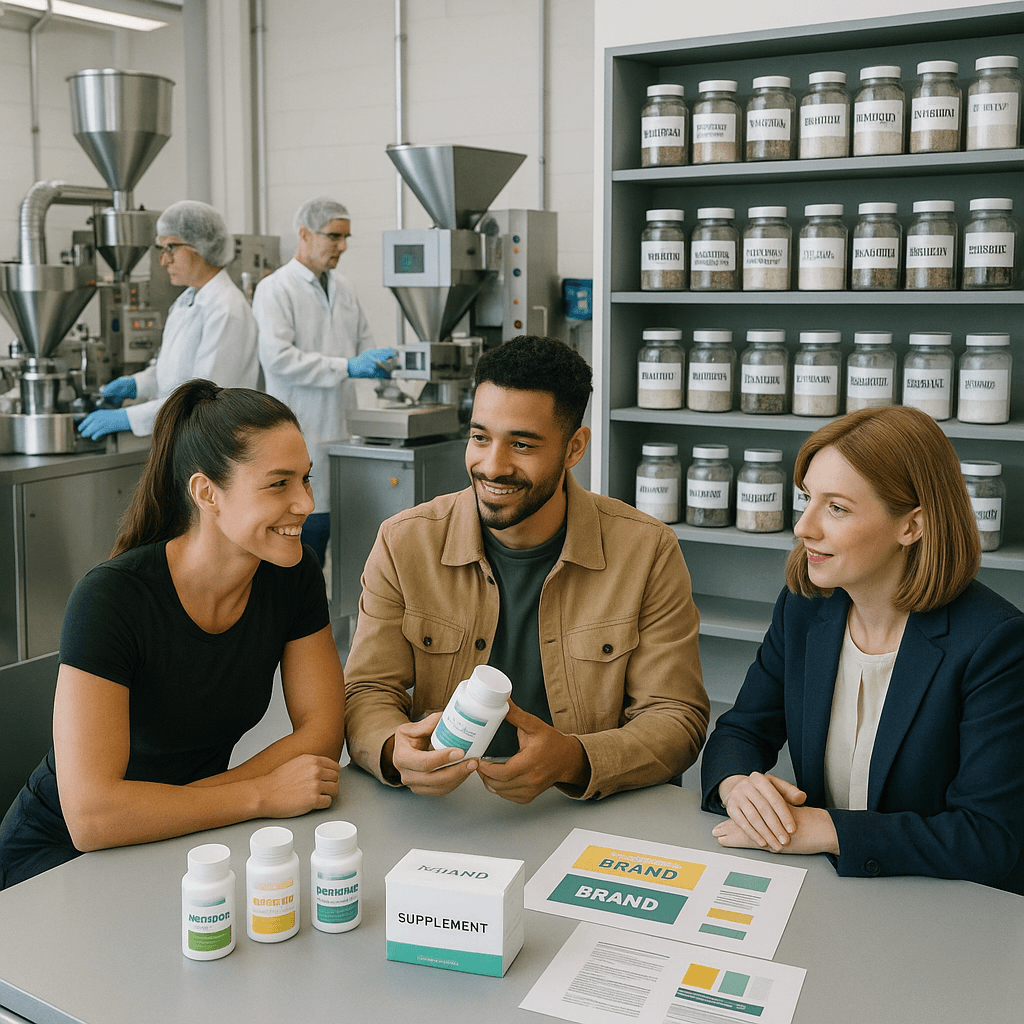

Launching a supplement brand in Europe used to mean high upfront costs, long timelines, and huge inventory risk. Not anymore. In 2025, low-MOQ (Minimum Order Quantity) manufacturing is unlocking a new era for agile, niche-focused wellness brands — and Europe is leading the shift.

Whether you're a health retailer, influencer, or entrepreneur, small-batch production is making it easier than ever to enter the market, test ideas, and scale quickly without overcommitting.

Here’s why low-MOQ is on the rise — and how smart brands are using it to stay lean, relevant, and profitable.

1. What Low-MOQ Means — and Why It Matters

Low-MOQ manufacturing allows brands to produce in small quantities — often between 500 and 2,000 units — compared to traditional minimums of 10,000 or more.

This makes it ideal for:

-

Fast trend testing

-

Limited or seasonal drops

-

Targeted products for niche audiences

-

Creator-led launches that move quickly

It’s a lower-risk path to validate ideas, collect data, and invest only in what sells.

2. Europe Is at the Forefront

Europe’s supplement market is more regulated — and more sophisticated. Low-MOQ models fit perfectly into this environment, offering flexibility without sacrificing quality or compliance.

Forward-thinking manufacturers in Germany, the Netherlands, the UK, and the Nordics now provide:

-

Capsule, powder, and gummy production in small batches

-

White-label and formulation support

-

EFSA-compliant label guidance

-

Custom flavoring and packaging options with minimal order requirements

This gives small brands access to premium-quality production without massive startup costs.

3. It’s Built for Fast, Trend-Driven Launches

Speed is everything when wellness trends shift fast. Low-MOQ manufacturing lets brands act on momentum — not miss it.

You can quickly:

-

Launch a nootropic bar for focus

-

Test an adaptogen blend tied to rising stress trends

-

Drop a seasonal collagen gummy

-

Ride a TikTok wave with chlorophyll drops or PMS support formulas

Brands that move first can set the tone — and define the trend.

4. It Reduces Risk for Startups and Creators

Not every idea hits. Smaller runs allow you to experiment without overextending — critical for startups, solo founders, and wellness retailers building in-house lines.

Perfect for:

-

Personal brands and micro-creators

-

Niche health collectives

-

Retailers or gyms testing own-label offerings

-

Clinics and spas building wellness extensions

Instead of committing to 10,000 units, you can start with 500 — and scale only when it’s proven.

5. It Aligns with Sustainable, Lean Models

Low-MOQ production supports cleaner, smarter business operations. It helps reduce waste, prevent overproduction, and support more sustainable packaging decisions.

It works seamlessly with:

-

Just-in-time inventory

-

Subscription or pre-order models

-

DTC-only or localized launches

Eco-conscious founders are pairing it with compostable pouches, glass bottles, and minimalist packaging to reduce footprint while maintaining impact.

6. It Enables Format and Formulation Innovation

Small-batch manufacturing isn’t limited to capsules anymore. Today’s facilities offer low-MOQ runs for formats that appeal to younger, lifestyle-focused buyers.

This includes:

-

Functional gummies

-

Stick packs for energy, hydration, or sleep

-

Liquid tinctures

-

Snack bars and functional food blends

Now, wellness brands can experiment across formats that fit real routines — not just supplement shelves.

7. It Supports “Drop Culture” and Built-in Scarcity

Limited production creates natural demand. Like fashion and beauty brands, wellness companies are now embracing drop culture: short runs, quick sellouts, and high engagement.

Think:

-

“Only 1,000 units available”

-

“New release this Friday — join the waitlist”

-

“First-come, first-serve on our nootropic sleep blend”

It builds buzz, reduces holding costs, and creates real-time feedback loops — all without sitting on thousands of units.

Final Thoughts

Low-MOQ supplement manufacturing is reshaping how products get built in Europe. It’s giving smaller brands the tools to launch faster, smarter, and with less risk — while staying compliant and delivering quality.

You don’t need big budgets or massive inventory to make a mark in 2025. You need the right idea, the right partner, and the ability to move fast when the opportunity strikes.

This isn’t just a manufacturing shift. It’s a brand-building advantage — and it’s changing who gets to win in wellness.